May 10:Scientists have developed low-cost Fe-based intermetallic powders that can be used as a corrosion-resistant coating for materials exposed to harsher environments like high temperature in thermal power plants where oxidation, corrosion, and wear and tear takes place simultaneously. The coatings showed 4 times increased corrosion resistance in the aqueous corrosive media than the mild steel.

Wear and corrosion cause major damage over a range of service temperatures. Hence, there is a need to protect the component surface with a suitable material for enhanced economic viability. Such surface coating on a turbine blade can enhance the service life and hence increases the operation hours of the turbine.

At present, thermally sprayed Chromium Carbide-Nickel Chromium Powder and Tungsten Carbide-Cobalt (Cr3C2-NiCr and WC-Co) (cermet) coatings have been widely used for superior wear and high-temperature oxidation resistance applications like thermal power plant turbine blades, aerospace engine blades, landing gear shafts, steel rolls in the paper industry. This is mainly attributed to their hardness, toughness, and better corrosion resistance under exposure to up to 550oC in the case of WC-Co coatings and up to 850oC for CRC-NiCr coatings. However, the powders are expensive due to the presence of Co and Ni elements. Besides, Cr is toxic in its hexavalent state. Replacement of these coatings with simple Fe-based coatings with novel microstructural constituents is very promising. In this regard, iron-based solid phases involving two or more metallic or semimetallic elements (intermetallics) can play a major role owing to their hardness and better corrosion resistance. However, their deployment is rather restricted by low ductility.

A team of scientists at the Centre for Engineered Coatings (CEC), International Advanced Research Centre for Powder Metallurgy & New Materials (ARCI), an autonomous R&D Centre of the Department of Science and Technology (DST), has addressed this by synthesizing Fe-based intermetallic powders and utilized the same for depositing the coatings using detonation spray coating (DSC) technique.

Besides, ARCI has developed gas atomized Fe aluminide powder and deposited it on mild steel substrates by DSC without any cracks or spalling. The coatings have demonstrated 4 times increased corrosion resistance in the aqueous corrosive media than the mild steel.

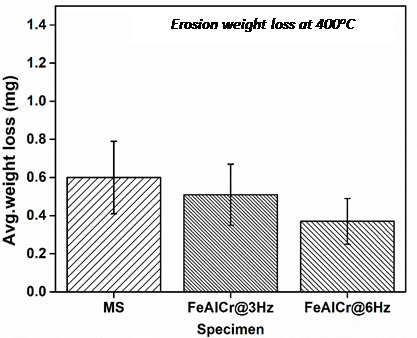

The coatings exhibited better corrosion resistance when Cr and Al are in a solid solution with Fe than in the Fe –rich phases. The coatings have demonstrated an increased wear resistance by 30-40% than the mild steel under solid particle erosion wear mode, implying that FeAlCr coatings can be used for high-temperature erosion resistance applications. More studies are currently underway to qualify the FeAlCr coatings for fireside corrosion protection of boiler components in collaboration with the NTPC, to enhance boiler life.

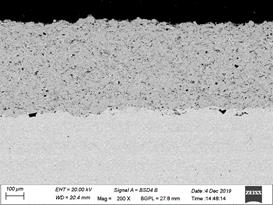

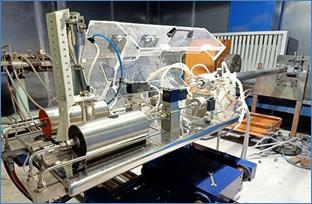

Fig.1 (a) A close view of ADSC process while the coating is in progress and (b) FeAlCr coating cross-sectional image deposited at 6Hz frequency

Fig.2 Detonation spray deposited iron aluminide coatings exhibiting higher erosion wear at 400oC than MS substrate (X-axis label may be suitably modified as Bare and Coated MS)

For more details, please refer article:

D. Vijaya Lakshmi, P. Suresh Babu, L. Rama Krishna, R. Vijay, D. Srinivasa Rao, G. Padmanabham, “Corrosion and erosion behavior of iron aluminide (FeAl(Cr)) coating deposited by detonation spray technique”, Adv. Powder Technol., 32 (2021) 2192-2201

<><><><>

Disclaimer: We donot claim that the images used as part of the news published are always owned by us. From time to time, we use images sourced as part of news or any related images or representations. Kindly take a look at our image usage policy on how we select the image that are used as part of the news.